The Brief: To develop and supply a full range of compliant medical examination gloves and sterile surgical gloves under a framework agreement for a period of two years.

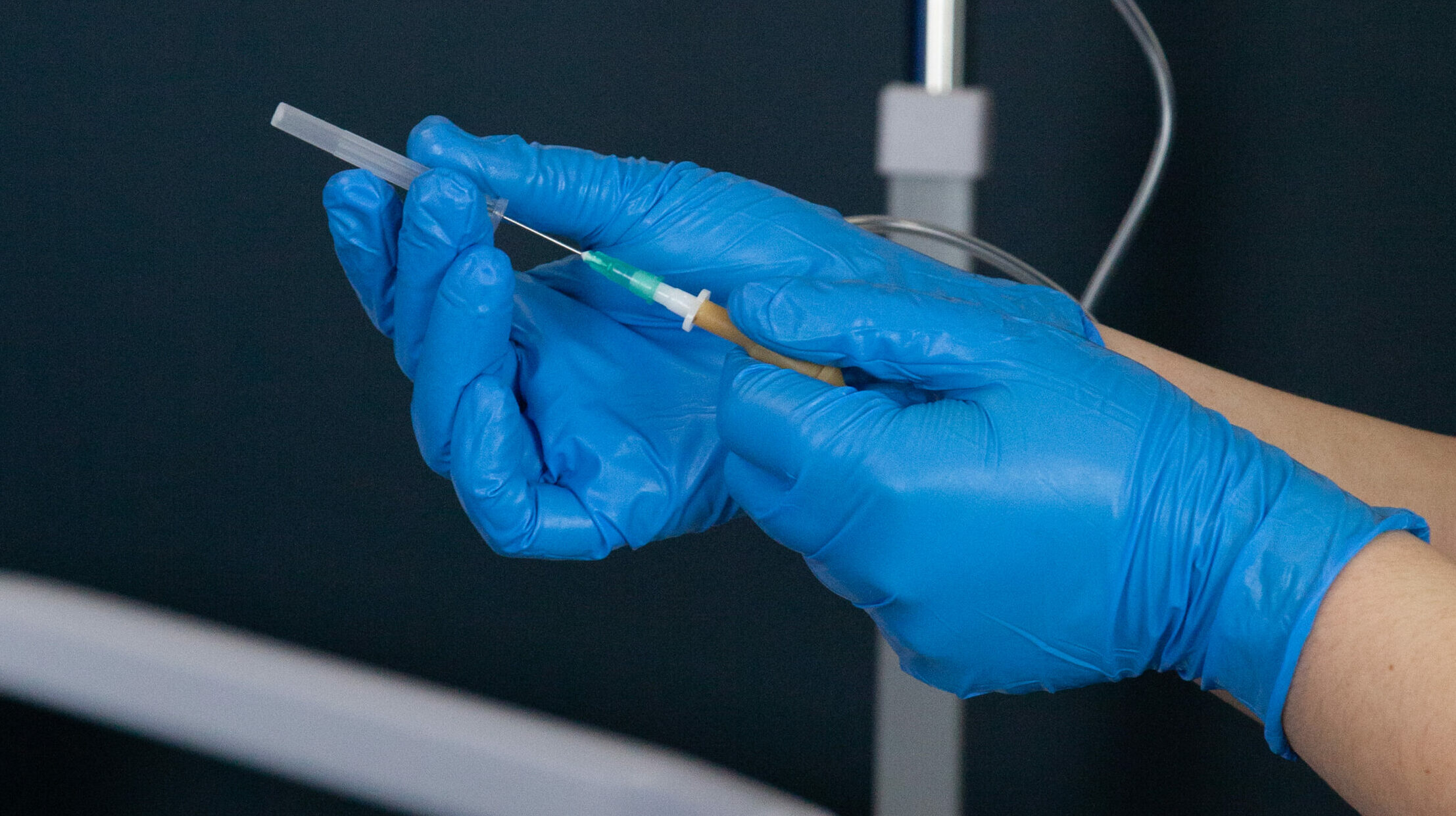

The Challenge: Drawing from the tough lessons of the Covid-19 pandemic, one of the largest healthcare procurement organisations needed to look at ways of shortening supply lines for nitrile gloves. This was a product typically manufactured in the far east. There was pressure to achieve 100% assured supply without the need to invest in a huge UK “buffer” stockholding of gloves in case of shipping delays. Medical supply chains worldwide were still facing disruption and unplanned demand from the pandemic. The tender required medical examination gloves and surgical gloves for use throughout a hospital in all departments to meet the high standards of the organisation’s supply framework.

As part of the framework requirements, the following quality assurance standards had to be met:

- Medical Devices Regulation 2017/745

- EU MDD 93/42/EEC

- UK MDR 2002

- Personal Protective Equipment Directive (EU 2016/425)

- EU PPE 89/686/EEC

- UK PPE 2016

- EN 455-1:2020

- EN 455-2:2015

- EN 455-3:2015

- EN 455-4:2009

- EN 556-1:2021

- EN 374-1:2016:2018

- EN 374-2:2019

- EN 16523-1:2015

- ISO 374-4:2019

- ISO 374-5:2016

- EN 556-1:2001

- ISO 16604:2004

- ISO 13485:2016/ ISO 9001:2000

- ISO 21420:2020

- Medical Device Reg 2017/745

- PPE Directive 2016/425

- Directive 2007/47

- Control of sub. Haz to health Reg 2002

Additionally, there were stringent KPIs measured monthly around factors such as delivery timing, invoicing, documentation, and data requests.

The Solution for Supplying Medical Examination Gloves and Surgical Gloves:

Supply Source used our “Double Diamond” methodology to define the product range offering, drawing on the very latest scientific innovations worldwide on nitrile glove manufacturing and packaging. We then pulled together a hybrid supply chain solution partnering with a pre-qualified factory in the far east alongside ad-hoc production capability from our own factory in Europe for stop-gap production capacity. This enabled SupplySource to offer the correct balance between outright value for money versus guaranteed “just-in-time” delivery capability. The ability to pivot to near-shore production at an hour’s notice also helps reduce carbon footprint.

We then set up a single point of contact in the UK for any communications such as mini competitions, tenders and technical queries within the framework. Our expert panel also engaged in regular product training sessions and innovation forums with users and product champions on trending subjects such as glove recycling schemes, glove formulation and factory production techniques for examination gloves and sterile surgical gloves.

Our pre-approved third-party compliance and regulatory experts were constantly on hand at both factories, and throughout the whole supply and logistics operation for regular product sampling, auditing and specialist technical advisory services where needed. globally.

Several of our sourced products were already approved, in use, and trusted within the healthcare procurement organisation on various frameworks and throughout the USA. In addition to this, we hold certifications such as 510K, EN374, CE and UKCA.